It is standard practice to assign commercial staff the control of the correctness of the data measured by the operators and of the data of the transport documents (or reservations) of the customers. In fact, the managers of the “operations” do not have the time to carry out immediate checks on each package, let alone notify the offices of the difference detected, particularly if we are in the presence of high volumes of goods and at days and times when the revenue is concentrated. The outcome of the checks through data analysis and the process of “defining” the notification procedures for changes is often carried out to the customer after several hours from receipt or days or at the end of the month.

This verification, however, takes place lagging behind the provision of the service which, out of respect for the SLA, provides for its immediate shipment (as soon as possible);

The lack of timeliness, often identified as inefficiency and lack of control of the supply chain, causes the generation of requests for integration of unplanned costs towards the customer with times too far from the shipment.

These events, although based on objective data that can no longer be demonstrated, if not testified, damage the relationship with the customer with the risk of losing him and the detection of discrepancies between what has been declared and detected often generates losses.

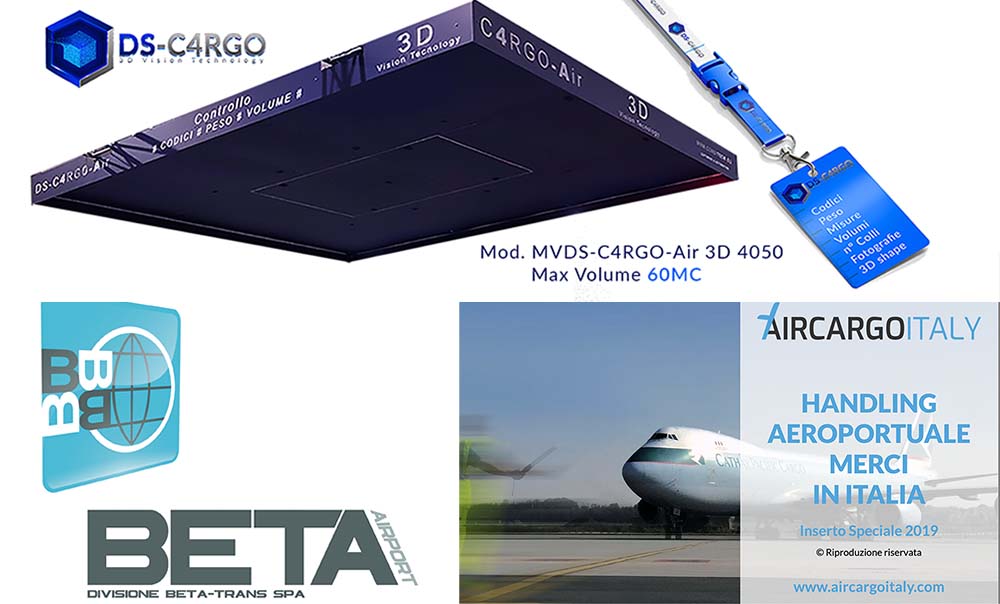

C4RGO, in addition to ensuring accurate, fast detections and data retention for sufficient periods to deal with any verification to solve problems, has a “Control & Congruity” module capable of alerting in real time, if the package / goods detected respects the “entry” data and the assigned volumetric class (weight density) ratio. The certification of the process ensures the correct tax procedure that allows the use of data for billing. All in real time!

For a 360 ° service, C4RGO VIEWER opens a direct line with customers and also follows the goods on the move, ensuring “testimonials” of the quality or otherwise of shipments even outside the company.